Dolphin Centrifuge is primarily an engineering company specializing in Alfa Laval industrial centrifuge system design & manufacture. We engineer each system to customer specifications to ensure robust design and functionality.

The Centrifuge Design Process

Our process typically starts with a lab-scale test on a customer sample. We evaluate the results, and based on the separation efficiency, we suggest a suitable centrifuge (with recommended options) to the customer.

If the customer decides to move ahead with our proposed system, Dolphin Centrifuge designs a preliminary process flow diagram which is sent to the customer for review and changes, if desired.

We finalize the system scope at this point. Electrical & mechanical drawings are also generated and sent to the relevant functions to execute.

In the final stage, all subsystems are checked and assembled to original drawings.

The completed system is wired and tested per Dolphin Centrifuge’s established procedures. We invite the customer to witness the final system testing at our facility.

Centrifuge System Design and Engineering include:

- GA, Layout, P&ID, Flow, and related drawings

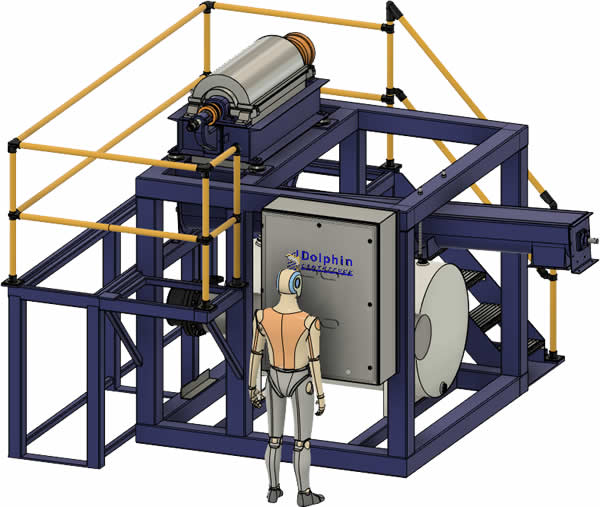

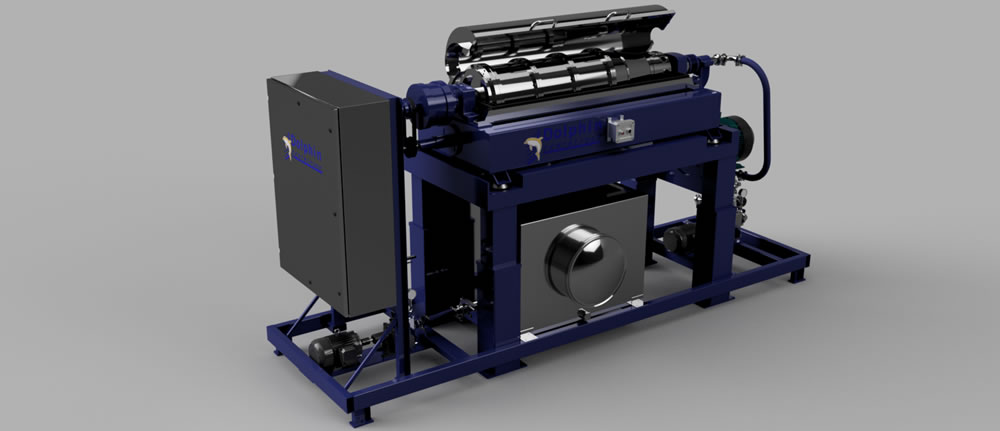

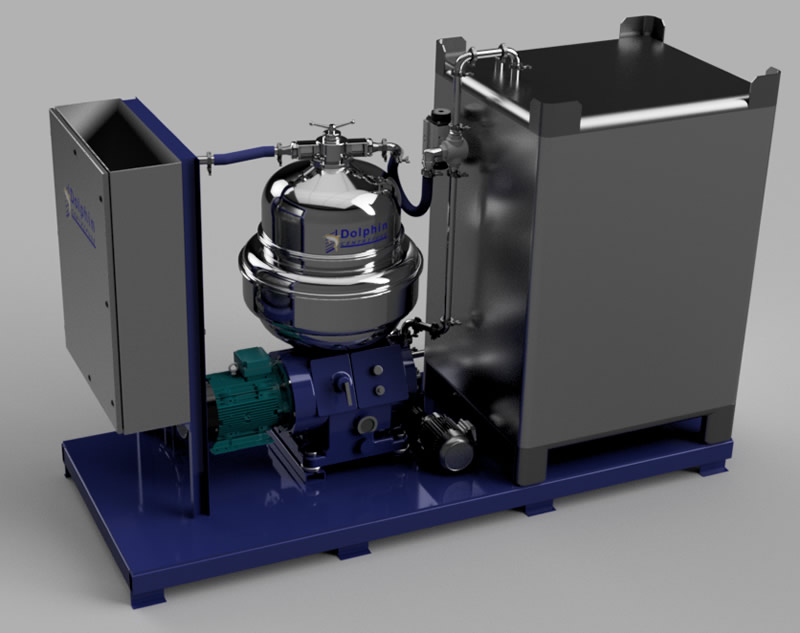

- 3D models of complete systems

- Electrical control system design and build

- PLC & HIM (Touchscreen) Programming

- Plant layout and piping design assistance

- Auxiliary system design and specification (Pumps, Heaters, etc.)

Site visit and consultancy

We conduct site visits to review your current processing setup and evaluate the possibility of an industrial centrifuge to enhance your ongoing process. Based on a site visit, our engineers can

- Evaluate your product on-site to determine centrifuge applicability

- Discuss any operational efficiency that an industrial centrifuge may gain

- Identify the type and size of centrifuge needed

- Locate the point in your current process best suited to utilize a centrifuge

- Recommend any related process modifications to improve the existing process setup

- Provide a ‘post-visit’ recommendations summary, as needed

We highly recommend any prospective centrifuge buyer consult a reputed centrifuge company with the experience and know-how to provide sound centrifuge-related advice before buying a capital-intensive centrifuge system.

Please contact Dolphin Centrifuge or call us at (248) 522-2573 to talk with our centrifuge engineers.