Table of Contents

Liquid humus fertilizer – How is it made?

To produce liquid humus, you first mix organic humus with water to make a slurry. After a predetermined residence time, you separate the water from the humus biomass. The separated water carries all the minerals and nutrients from the humus. This fluid is liquid humus.

Large-scale production of liquid humate

For large-scale production, mechanical separation of humus biomass is the most efficient way to produce liquid humus. An industrial centrifuge separates humus biomass from the water on a commercial scale. High centrifugal force is very efficient for separating biomass solids from the slurry.

A decanter is a high-capacity, flow-through type centrifuge, separating a large proportion of humus biomass (up to 50%) from water. This continuous process produces liquid humus fertilizer and dry humus biomass. The centrifuge model shown is an Alfa Laval NX 314 Stainless Steel Decanter Centrifuge for continuous humus dewatering.

Lab Scale Centrifuge Testing

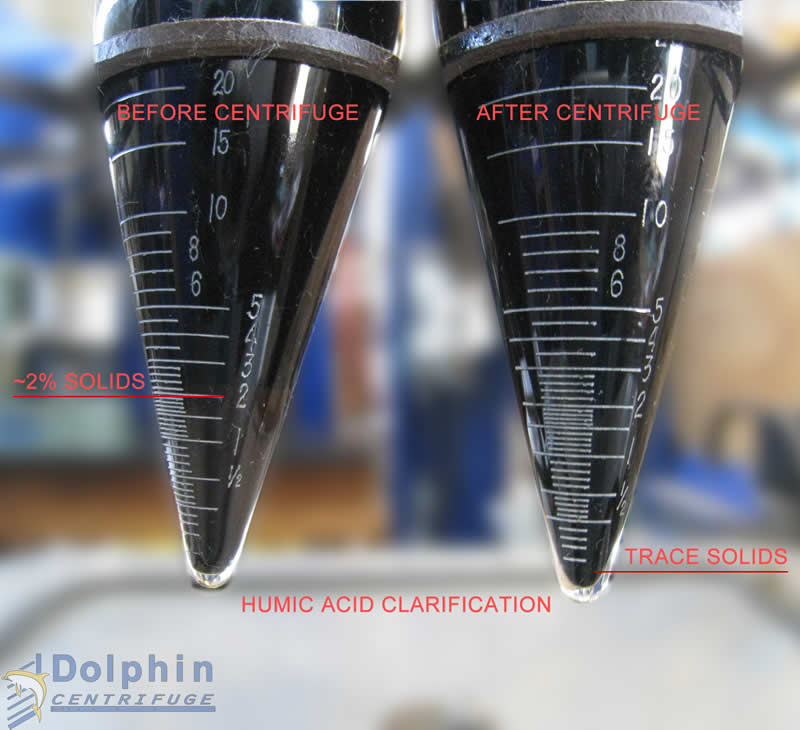

Small volumes of humic acid were processed through a lab-scale disc stack centrifuge to evaluate the separation efficiency of the centrifuge. The following photograph shows the results of the testing.

The following photograph shows the contents of the disc stack centrifuge bowl that has retained all the solids from the humic acid sample.

Specifications

| Application | Humus Fertilizer Separation |

| Capacity | 30 GPM on Liquid Humus Slurry |

| Motor Power | 15 HP |

| Material Of Construction (MOC) | 316L Stainless Steel |

| Dimensions | 8′ (L) x 4′ (W) x 4′ (H) |

| Weight | 2500 Lbs |

| Max. G-Force | 3150 G |

| Max. Bowl Speed | 4,000 RPM |

| Expected Solids Dryness | < 5% Moisture |

Higher capacity decanters are available – contact Dolphin Centrifuge for details.