Overview Various industries use decanter centrifuges to separate bulk sludge or solids from fluids. From the separation of aromatic herbs from tincture or alcohol to the separation of zinc salts from the chemical broth, all types of industries use Alfa Laval decanter centrifuges. The applications for decanter centrifuges are prevalent in all industries, such as… Continue reading Decanter Centrifuge Applications | Comprehensive List of Uses from A to Z

Category: Decanter Centrifuge Blog

Smallest Industrial Centrifuges | Decanter and Disc-Stack | Specifications & Applications

Smallest Decanter Centrifuge The smallest decanter centrifuge is the Sharples P-660 which has a bowl diameter of approximately 6” and a bowl RPM of 6,000. The operating g-force is 3,070 Gs at full speed. The P-660 has a cyclo gearbox and uses a 7.5 HP motor. The Sharples P-660 decanter is an ideal lab-scale centrifuge… Continue reading Smallest Industrial Centrifuges | Decanter and Disc-Stack | Specifications & Applications

Containerized Industrial Centrifuge | Types, Layout, Applications, and Benefits

What is a containerized industrial centrifuge? A containerized industrial centrifuge is an industrial centrifuge that is installed or housed within an intermodal shipping container. This module is a fully self-contained system with plug-and-play functionality. The enclosure includes all the accessories required to operate the industrial centrifuge. Types of Containerized Centrifuges Though it is possible to… Continue reading Containerized Industrial Centrifuge | Types, Layout, Applications, and Benefits

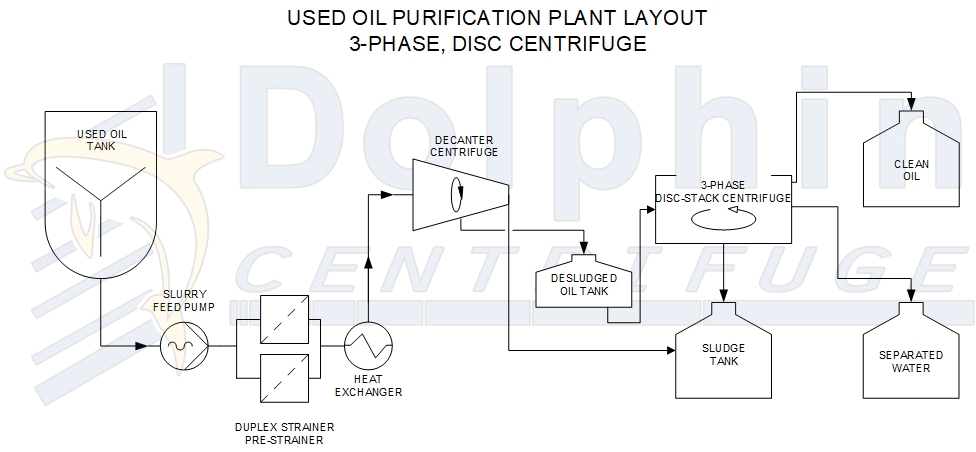

Used Oil Centrifuge Plant with 6 MGY Capacity – Layout, Benefits, and Equipment Specifications

For commercial or large-scale processing of used oil, centrifuges play a vital role in the separation process of water and sludge. This article discusses the typical layout of a used oil plant using industrial centrifuges, highlighting the benefits of centrifuges over conventional heating and settling methods. Plant Layout A used oil centrifuge plant layout has… Continue reading Used Oil Centrifuge Plant with 6 MGY Capacity – Layout, Benefits, and Equipment Specifications

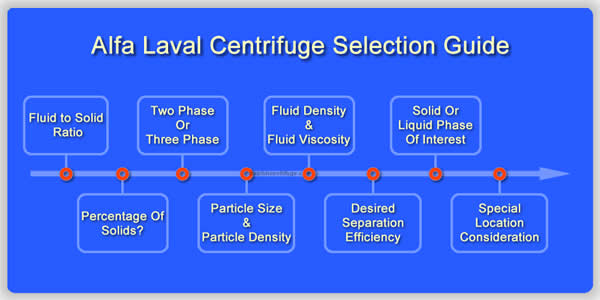

Alfa Laval Centrifuge Selection Guide | Decanter or Disc Stack

The Alfa Laval centrifuge selection guide helps users identify the optimum centrifuge based on process fluid properties for their specific application.

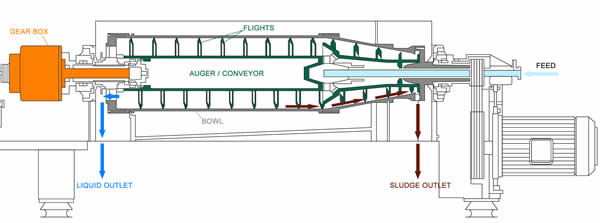

Dewatering Centrifuge | Operation, Animation, Uses, Benefits

A dewatering centrifuge is an industrial centrifuge specifically designed to dewater, i.e., separate water from sludge. Water separation from a slurry thickens the sludge and reduces the volume of wastewater for disposal. Therefore, this centrifuge is also known as a sludge-thickening centrifuge. Operation The operation of a dewatering centrifuge can be simply explained as follows.… Continue reading Dewatering Centrifuge | Operation, Animation, Uses, Benefits

9 Steps to Picking The Right Industrial Centrifuge

Considering purchasing an industrial centrifuge but unsure where to begin? Even after thorough research, it’s common to have lingering doubts and questions. Industrial centrifuges are significant capital investments that require meticulous consideration. With our 40 years of expertise in the industrial centrifuge sector, we guide prospective buyers toward making informed decisions. We’ve distilled the centrifuge… Continue reading 9 Steps to Picking The Right Industrial Centrifuge

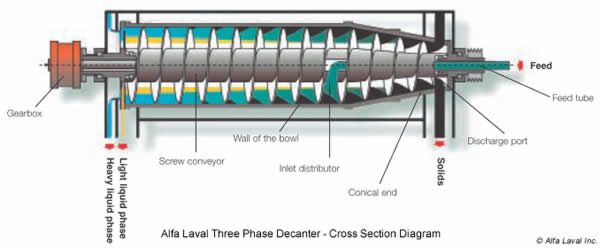

Three Phase Decanter | Working, Benefits, Specs, Applications

A three-phase decanter is a centrifugal separator that separates two immiscible liquids while simultaneously separating the solids. The liquid phases discharge through discrete outlets, and the solids eject out of the decanter’s sludge nozzles. Working Principle The 3-phase separation occurs in the horizontally rotating bowl of the decanter centrifuge. A fixed inlet tube feeds the… Continue reading Three Phase Decanter | Working, Benefits, Specs, Applications

Difference Between Decanter and Disc Centrifuge | Technical Comparison

30-Second Take-Away The main differences between a decanter and disc-stack centrifuge are: This article compares the different technical aspects of decanter centrifuges and disc centrifuges. We will compare all the factors important to the end-user. These will include physical, operational, performance, and maintenance factors between these centrifuge types. Overview of Decanter and Disc Centrifuge Operation… Continue reading Difference Between Decanter and Disc Centrifuge | Technical Comparison

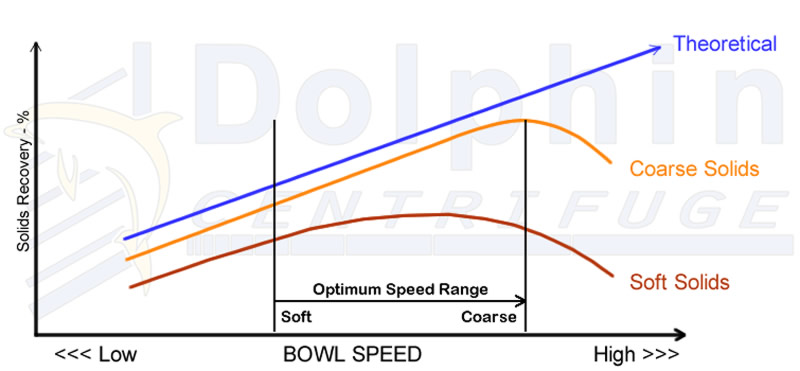

5 Ways to Optimize Decanter Performance | Illustrated Guide

30 Second Summary Takeaway Decanter centrifuge performance optimization involves tuning or adjusting specific operating parameters to improve the separation efficiency of the decanter. In this article, we discuss the 5 most effective and straightforward ways to achieve optimal decanter operation. We will address the following typical questions related to the optimization process. Pond Depth The… Continue reading 5 Ways to Optimize Decanter Performance | Illustrated Guide