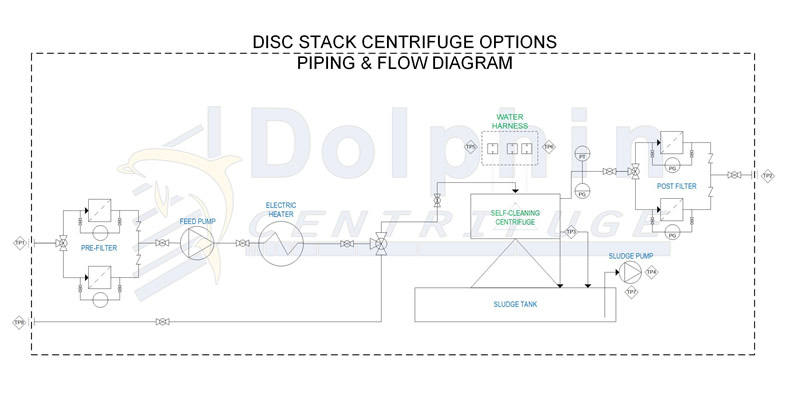

Disc stack centrifuge performance depends on operational parameters that the use of optional equipment can enhance. The following is a detailed list of disc stack centrifuge options and the benefits of each option. We also indicate alternatives that centrifuge customers can provide on their side to extract the same benefits. It is necessary to describe… Continue reading Disc Stack Centrifuge Options | Benefits, Details & Alternatives

Category: Disc Centrifuge

Smallest Industrial Centrifuges | Decanter and Disc-Stack | Specifications & Applications

Smallest Decanter Centrifuge The smallest decanter centrifuge is the Sharples P-660 which has a bowl diameter of approximately 6” and a bowl RPM of 6,000. The operating g-force is 3,070 Gs at full speed. The P-660 has a cyclo gearbox and uses a 7.5 HP motor. The Sharples P-660 decanter is an ideal lab-scale centrifuge… Continue reading Smallest Industrial Centrifuges | Decanter and Disc-Stack | Specifications & Applications

Containerized Industrial Centrifuge | Types, Layout, Applications, and Benefits

What is a containerized industrial centrifuge? A containerized industrial centrifuge is an industrial centrifuge that is installed or housed within an intermodal shipping container. This module is a fully self-contained system with plug-and-play functionality. The enclosure includes all the accessories required to operate the industrial centrifuge. Types of Containerized Centrifuges Though it is possible to… Continue reading Containerized Industrial Centrifuge | Types, Layout, Applications, and Benefits

Disc Stack Centrifuge for Offshore Applications: Uses, Specifications & Capacities

Applications Offshore applications of disc stack centrifuges use these separators on offshore oil and gas platforms. These centrifuges perform various separation duties essential for the regular operation of such platforms. Some of the leading centrifuge applications are listed below. Diesel Fuel Diesel fuel is the primary fuel source for generators on offshore facilities that provide… Continue reading Disc Stack Centrifuge for Offshore Applications: Uses, Specifications & Capacities

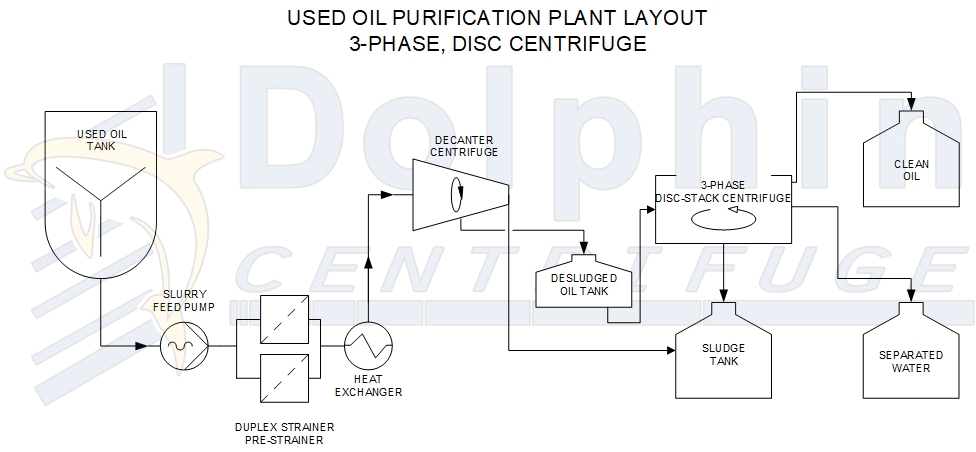

Used Oil Centrifuge Plant with 6 MGY Capacity – Layout, Benefits, and Equipment Specifications

For commercial or large-scale processing of used oil, centrifuges play a vital role in the separation process of water and sludge. This article discusses the typical layout of a used oil plant using industrial centrifuges, highlighting the benefits of centrifuges over conventional heating and settling methods. Plant Layout A used oil centrifuge plant layout has… Continue reading Used Oil Centrifuge Plant with 6 MGY Capacity – Layout, Benefits, and Equipment Specifications

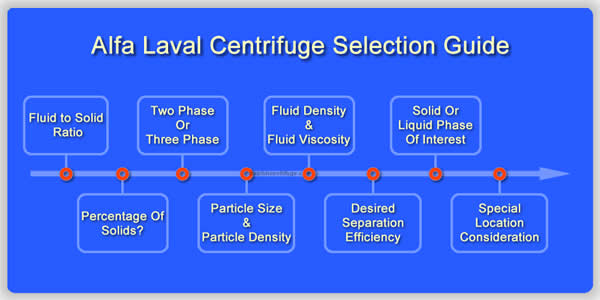

Alfa Laval Centrifuge Selection Guide | Decanter or Disc Stack

The Alfa Laval centrifuge selection guide helps users identify the optimum centrifuge based on process fluid properties for their specific application.

Disc Stack Centrifuge Parts | Availability, New vs. Generic, Sources

Disc stack centrifuge parts are specific to individual centrifuge models and differ between centrifuge manufacturers. Each centrifuge manufacturer has a specific centrifuge design that dictates the centrifuge parts. Centrifuge Construction The overall construction of most standard disc stack centrifuges is similar. They have a low-speed motor (1,800 RPM) that powers a bull gear that rotates… Continue reading Disc Stack Centrifuge Parts | Availability, New vs. Generic, Sources

Alfa Laval Disc Centrifuge Accessories | Recommendations and Benefits

The end-user can implement Alfa Laval disc centrifuge accessories to enhance the centrifuge performance by conditioning the process fluid, ease of operation, and centrifuge effluent handling. In this article, we discuss the various Alfa Laval disc centrifuge accessories and their benefits. It is important to note that these centrifuge accessories are suitable for all industrial… Continue reading Alfa Laval Disc Centrifuge Accessories | Recommendations and Benefits

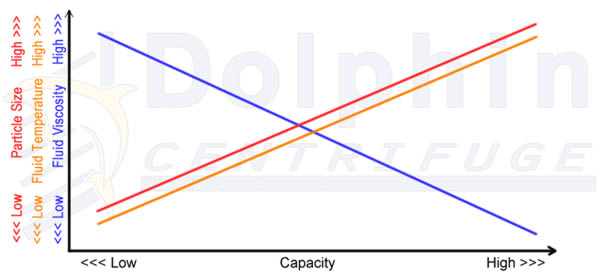

Disc Stack Centrifuge Capacity | Rated vs. Actual | Factors to Consider

Disc stack centrifuge capacity is often confusing to first-time centrifuge customers primarily due to the wide range of capacities mentioned by used equipment sellers, online literature, and general users. So, in this article, we will explain the difference between swallowing capacity, rated capacity, and actual real-world capacity of disc stack centrifuges. We will also explain… Continue reading Disc Stack Centrifuge Capacity | Rated vs. Actual | Factors to Consider

Disc Stack Centrifuge Troubleshooting | Clogged Bowl Discs

Excessive sludge can potentially clog the bowl discs in a disc stack centrifuge. If the sludge enters the inter-disc space, it blocks the passage for fluid to pass between discs. This condition is known as a clogged disc stack, drastically affecting the centrifuge performance. Clogged bowl discs can also be a safety issue and should… Continue reading Disc Stack Centrifuge Troubleshooting | Clogged Bowl Discs