Table of Contents

A decanter centrifuge is an industrial centrifuge that continuously separates solids from liquids. The separation in the decanter occurs due to the high centrifugal force generated by its rotating bowl.

Solid particles need a higher density than liquid for a decanter centrifuge to work.

Given its separating abilities, the decanter finds a variety of applications in biotechnology separation, oil fields, wastewater treatment, the food industry, hemp processing,

Alfa Laval decanter centrifuges – detailed information.

How Does a Decanter Centrifuge Work?

A decanter centrifuge works by exerting a high centrifugal force on the slurry of solids and liquids. A rotating conveyor pushes out the heavier solids that settle on the decanter wall. The lighter liquid exits the decanter through the liquid outlet port on the other end of the bowl.

Continuous process decanter centrifuges can process a large volume of fluids with sludge. Centrifugal force (upwards of 3,000 g) causes graded settling and separates the fluid from small sediment (50µ).

The rotating bowl has a concentric scroll that rotates at a differential speed to that of the decanter bowl. This speed differential allows the scroll to transfer the separated sludge.

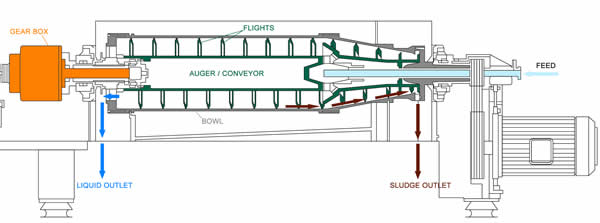

Cross-Section Diagram

The following diagram shows the cross-section of a typical decanter centrifuge.

Animation

Working Principle

The separation of fluid from the sludge occurs inside the rotating decanter bowl. One can explain the internal working as follows.

- Feed Introduction: The slurry is fed into the machine through an axial feed tube, injecting it into the conveyor. The tube conveys the slurry to the center of the conveyor feed chamber.

- Acceleration / Dispersal: The injected slurry strikes against an accelerator in the conveyor feed zone. This action accelerates the flow outward through the feed ports into the bowl, forming a ‘pond.’

- Separation: The solids of higher density displace the liquid and settle to the bowl’s wall. The conveyor continuously scrolls the solids up the angled conical part (beach).

- Auger Rotation: The bowl-mounted gearbox causes a differential rotation between the conveyor and the bowl.

- Sludge Discharge: The flights push the separated sludge up the bowl’s conical part (beach). The solids exit the bowl through 360° discharge ports at the rear end.

- Fluid Discharge: The clarified liquid rises to the pond’s surface and flows over the dams in the front bowl hub. At this point, the liquid discharges from the bowl.

Factors Affecting Performance

Certain decanter features have a direct impact on the performance of the decanter. These factors are adjustable for optimization.

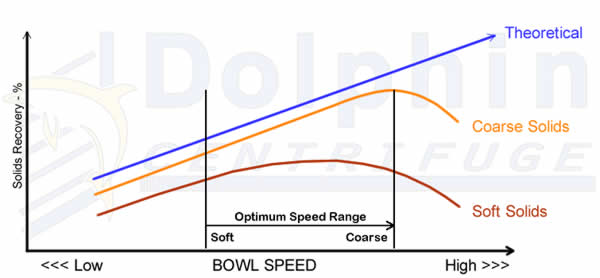

- Decanter Bowl Speed: The bowl speed or RPM signifies the effective centrifugal force generated by the decanter. Depending on the fluid and type/density of solids, the centrifugal force is the key factor affecting performance.

- Auger or Conveyor Speed: The relative rotation of the auger versus the bowl relates to the speed at which the separated sludge is conveyed out of the bowl. High sludge content applications require a fast conveyor speed to maximize efficiency.

- Pond Depth: The thickness of the fluid layer formed around the bowl’s inner wall is the pond depth. Deeper ponds lead to clearer centrate and wetter solids. Shallower ponds lead to dryer solids and murkier centrate.

Weir plate adjustments allow pond depth changes. Example weir plates are shown below. - Beach Angle: The angle of the conical part of the bowl is known as the beach angle. Varying the beach angle has a direct impact on the separated sludge dryness.

- Conveyor Pitch: The distance between the conveyor flights is the conveyor pitch. A shorter pitch enhances the decanter’s solids’ separation capacity and increases the torque on the gearbox.

Decanter Performance Optimization provides a detailed insight into optimizing the factors mentioned above for maximum effectiveness.

Types of Decanters

Decanter centrifuges are available in 2 configurations, namely 2-phase and 3-phase. In other words, solid-liquid and solid, liquid, liquid separation.

2 Phase

The two-phase separator is a solid-liquid separator. In other words, it separates the fed slurry into a solid phase and one liquid phase.

Most de-sludging duties use a two-phase design. These include industrial sludge thickening, municipal wastewater, hemp biomass separation, etc.

Tricanter is also known as Three-Phase Decanter.

A 3-phase type separates solids from 2 immiscible fluids. In other words, a 3-phase decanter centrifuge produces a solid phase and two separate liquid phases.

For example, a 3-phase configuration separates crude oil from tank bottom sludge and water. Olive oil separation from water and biomass is another example.

Explosion Proof

A decanter centrifuge with applications in hazardous or explosive environments needs special design considerations. The special-purpose centrifuges are referred to as Explosion Proof Decanters.

The NEC classification for these areas in the domestic market comes under the Class 1 Division 1 zones. Therefore, it is common to refer to these decanters as Class 1 Division 1-rated machines.

Environments, where flammable gases, fluids, or dust are present, require using explosion-proof decanters. Refiners, Offshore Oil Platforms, Mines, Chemical Plants Effluent, and similar locations mandate these classifications.

Our article about Explosion Proof Centrifuges provides detailed information about these centrifuge classifications for explosion-proof or hazardous areas.

Advantages

Decanters compete with other separation technologies such as filter presses, screw presses, etc.

Though all these different equipment have advantages, decanters have some specific benefits. These benefits are due to the decanter centrifuge being a mechanical separator.

All the other technologies use media separation, which has inherent drawbacks.

The following is a list of advantages of decanter centrifuges over filtration methods.

1. Process Adaptability:

Decanter centrifuges can easily handle product variations. They can produce consistent separation results even with varying flow rates. These centrifuges can handle process fluid mix variations without final product degradation.

2. Compact Dimensions:

Decanter centrifuges have a smaller footprint than belt and filter presses of similar capacity. This small size allows for the installation of decanters in small, confined spaces.

3. Vapor Tight Design:

The basic design of decanters includes a rotating bowl in an enclosed chamber. This design prevents odors, undesirable fumes, and gases from contaminating the operating space.

4. Low Labor Costs:

Fluid separation through a decanter is practically an automatic process. This process requires minimal manual attendance service, thereby reducing associated labor costs.

5. Reduced Operating Cost:

Since only worn parts are replaceable in decanter centrifuges, it minimizes long-term operating costs. Filter media need constant replacement in other separation methods.

6. Long Service Life:

Robust design and construction are primary features of decanter centrifuges. Besides, high-quality construction material helps decanters perform with reliability for extended periods. Replaceable wear parts such as sludge discharge ports enable long service life.

7. Easy and Quick Installation:

Decanter centrifuge systems are self-contained and are thus easy to install. The speed and ease of commissioning allow them to be productive quickly.

8. Wide Range of Particle Separation:

The decanter separates particle size ranges from 1 Micron to 15 mm or larger. This ability gives decanters a significant advantage over media filters with fixed apertures.

9. Three-Phase Separation:

Besides separating solids from liquids, three-phase decanters (tricanters) also separate immiscible liquids. This separation co-occurs with solids separation.

10. Easy Adjustments for Desired Separation Phase:

The decanter centrifuge user can adjust sludge dryness or centrate clarity quickly and easily. This ease of phase quality adjustment is an added benefit lacking in filtration equipment.

The installed weir plate controls the separated phase dryness by changing the pond depth.

Disadvantages

A decanter centrifuge has certain disadvantages when compared to other solid-liquid separation equipment. The following is a list of the main limitations.

1. Capital Expense:

Decanter centrifuges have a higher cost than filters and similar separation devices. Performance improvement and wear preventive options can further add to this cost.

2. Light Particle Separation

Centrifuges leverage the difference in specific gravities between solids and liquids to separate. When the solids (such as biological cells) have a specific gravity close to the liquid, the decanter cannot separate them.

3. Power Requirement:

Large horsepower motors power decanter centrifuges. Compared to filtration machines, these drive motors need a higher operating current.

4. Noise and Vibration:

Decanter centrifuges have heavy rotating bowls and other rotations of heavy masses cause vibrations that lead to noise. These decanters create noise levels in the 70-80 dB(A) range.

Also, read our Alfa Laval Centrifuge Selection Guide.

Specifications

The following table lists the essential technical specifications of Alfa Laval decanter centrifuges.

| Model | Alfa Laval NX-314 | Alfa Laval NX-418 |

| Material of Construction (MOC) | 316L Stainless Steel | 316L Stainless Steel |

| Max. Bowl RPM | 4,000 | 4,000 |

| Bowl Diameter | 14″ (353 mm) | 14″ (353 mm) |

| Bowl Length | 40″ | 68″ |

| G-Force (Centrifugal Force) | 3,150 G’s | 3,150 G’s |

| Particle Size Separation Range | 50 µm to 1/2″ | 50 µm to 1/2″ |

| Max. Processing Capacity | 50 GPM | 170 GPM |

| Drive Power | 15 HP | 25 HP |

| Size (Footprint) | 3′ x 6′ x 5′ (H) | 3′ x 10′ x 5′ (H) |

| Differential Speed | 1 ~ 25 RPM | 1 ~ 50 RPM |

| Gearbox Type | Planetary Gearbox; 2.5 kN-M Torque | Planetary Gearbox; 2.5 and 3.5 kN-M Torque |

Material of Construction

The Alfa Laval NX 418 and NX 314 decanters are designed for applications of crude oil, mineral oil, and wastewater. Therefore, the material used in its construction is well suited for such uses. The following table lists the various components of the centrifuge and the material it is made of.

| Bowl Body | 316L Duplex Stainless Steel |

| Conveyor / Auger | 316L Duplex Stainless Steel with Tungsten Carbide Hard Surfacing |

| Vessel / Collecting Cover | 316L Duplex Stainless Steel |

| Gearbox | Hardened Steel – Planetary Gearbox |

| Base Frame | Carbon Steel with Epoxy Base and Top Coat Paint |

Modification for Special Applications

Special modifications are available for Decanter centrifuges for specific applications. Some of these adaptations are in the following table.

| Decanter Modification | Technical Details | Benefits |

| Tungsten Carbide Tiles | Multiple Tungsten Carbide hard-surface tiles welded to the conveyor flight edge. | Erosion protection of conveyor in highly abrasive sludge applications. |

| Back Drive Motor | Allows conveyor differential speed control. | Centrifuge adaptation under varying sludge load. |

| Nitrogen Blanketing | Nitrogen purging of the bowl surrounding the vessel (coffin). | Prevent oxygen contact with process fluid in oxygen-sensitive and flammable fluids. |

| Clean Fluid Tank | Collection tank for centrate falling out under decanter. | A modular system eliminates the need to raise the decanter to collect fluid. |

| Separated Sludge Conveyor | Conveyor sub-assembly under sludge outlet. | Eliminates the need to elevate the decanter for sludge collection. |

Manufacturers

Prospective buyers should consider some crucial aspects listed below before selecting and purchasing a decanter.

There are many decanter centrifuge manufacturers worldwide. Yet, it is essential to consider the manufacturer’s origin and legacy—especially given these machines’ initial cost and sophistication.

Long-term durability and field experience have proven the reliability and longevity of a few brands.

Alfa Laval is the top-quality manufacturer of centrifuges for over 100 years! Alfa Laval is a ‘name brand’ among centrifuge manufacturers. It is not uncommon to see Alfa Laval centrifuges last 50+ years.

Sizing

A decanter centrifuge comes in different designs and sizes. For optimum process efficiency, sizing is a critical parameter in selection.

A machine rated 100 gallons/minute of wastewater will likely process 20 gallons/minute of thick waste oil. Therefore, the user should carefully consider the process-fluid properties and decanter design features to size a proper decanter for each process.

Other design features such as auger pitch, beach cone angle, gearbox ratio, bowl speed, and auger speed significantly affect decanter sizing. Consulting an experienced centrifuge company with extensive application history is highly desirable and recommended.

Equipment Cost

Decanter centrifuges are capital equipment based on their expected operating life and durability. Their price depends on the manufacturer and size/capacity.

A new machine (from a quality, established manufacturer) starts from around $50K for a small capacity unit to over $1M for a large capacity machine. Accessories such as explosion-proof upgrades, control systems, pumps, etc., are optional and add to the cost.

Remanufactured models range from 40% to 60% compared to new models of similar capacity.

Operating Costs

Decanter centrifuge operating costs can be categorized as follows.

Power Consumption

The only power-consuming component of these centrifuges is the motors. Consider the following example:

Your cost per kWh: 25 ¢

Capacity: 5 GPM

Volume processed per hour: 300 Gallons

Cost per gallon processed: 25 ¢ / 300 = 0.08 ¢

Spare Parts

The availability of spare parts is an important consideration for the longer-term operating costs.

For ‘no-name’ decanters, the buyer wholly depends overseas on a single source manufacturer. Stock, availability & part cost are essential considerations for critical equipment.

On the other hand, generic spare parts are readily available for established, brand-name manufacturers. The manufacturers themselves have parts stock worldwide for quick delivery.

Labor

Decanter centrifuges are continuous processing, self-contained machines, which means there are no operating labor costs involved. Only service and maintenance require labor.

Chemical Use

Specific processes need chemicals to aid separation, an extra cost the buyer should consider.

Maintenance & Service

Decanters from high-quality manufacturers are generally very reliable. As long as the user maintains them per the manufacturer’s recommendation, they provide reliable service.

Ongoing maintenance involves periodic gearbox oil changes and bearing lubrication. The primary service involving bearing replacement is every few years, depending on the severity of use.

Processes involving abrasive solids, such as drilling mud, will need scroll or screw rebuild based on wear rate.

FAQ

What are the uses of a decanter centrifuge?

Decanter centrifuges include thickening of wastewater sludge, separation of solids from crude oil, sewage treatment, chemical precipitate concentration, fish meal separation, separation of carbon black, grease trap waste de-sludging, etc.

What are the phases separated by a decanter centrifuge?

A decanter centrifuge separates the solids or sludge from liquids. The separated sludge is also known as the cake. The clarified liquid phase discharged from the decanter is known as the centrate.

What is the difference between a wine decanter and centrifugal decanter?

A wine decanter is used to separate or settle out the sediment from wine using gravity. A centrifugal decanter uses rotation to magnify the force of gravity thousands of times to separate sediment from liquids for industrial uses.

What is the typical centrifugal force generated by a decanter centrifuge?

A decanter centrifuge generates over 3,000 times the force of gravity. Smaller decanters rotate at a higher RPM than larger diameter decanters, but the effective centrifugal force is similar.

Are decanter centrifuges nosiy?

Decanter centrifuges are rotating devices and therefore generate noise during operation. The typical noise level of an operational decanter is in the 70 to 80 dB(A) sound level.

Can the sludge dryness of a decanter centrifuge be adjusted?

The dryness of the sludge separated by a decanter centrifuge is adjustable by changing some of the settings of the decanter. For example, by reducing the liquid pond depth, a user may get dryer separated sludge.

What are the main parts of a decanter that are subject to excessive wear?

The sludge conveyor and sludge discharge ports are the main parts of a decanter that are subject to wear in a decanter centrifuge. The wear is due to the constant movement of abrasive particles across the surface of these parts.

New versus Remanufactured

New machines from branded manufacturers like Alfa Laval is the first choice. However, given the cost of new models, buyers often seek remanufactured decanters from trusted and established companies.

Important considerations before buying a remanufactured decanter centrifuge

- Manufacturer of the original centrifuge.

- Credentials & experience of the re-manufacturer.

- Previous use.

- Wear status of the bowl and conveyor.

- Parts used in the rebuild – especially bearings.

- Balancing of major rotating components.

- Vibration check and complete testing of the centrifuge assembly per OEM specifications.

We have condensed 35 years of our centrifuge specialty into a 9 Step Guide to Selecting Your Perfect Industrial Centrifuge.

Applications

Decanter centrifuges are perfect for separating liquids from high amounts of solids. Realistically, they can continuously separate over 50% (v/v) solids from liquids. Decanter centrifuges can produce up to 4000 g’s of centrifugal force, sufficient to separate particles down to 50µ.

The following are some of the industries using our remanufactured decanters.

- Crude Oil Tank Bottoms

- Oilfield Drilling Mud

- Waste Oil De-Sludging

- Hemp Biomass Solvent Extraction

- Industrial Wastewater

- Municipal Sludge Dewatering

- Fish Meal Stick-water

- WVO De-Sludging

- Paint Industry Wastewater

- Rendering Plants Sludge Thickening

- Food Industry Waste Streams

Remanufactured By Dolphin Centrifuge

Dolphin Centrifuge has been remanufacturing Alfa Laval decanters for over 30 years. We have a similar experience with Sharples centrifuges.

Our remanufactured decanter centrifuges come with a warranty, lifetime technical support, on-site startup, and training and can be built to suit your application (as shown above).

Our remanufacturing process follows OEM guidelines. We strictly adhere to all the remanufactured decanter considerations listed above.

We have a stock of over 50 Decanters at our factory in Warren, MI. Our stock machines are carefully selected based on their previous use. We stock gently used units from olive oil or other similar benign applications.

We avoid stocking decanters from drilling mud or other abrasive applications.