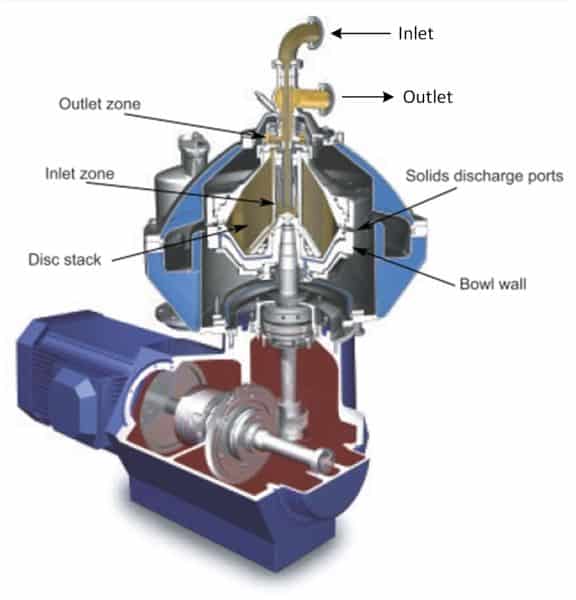

An Oil Centrifuge is a continuous process centrifuge machine capable of continuously separating Water and Sludge from any oil.

An Industrial Oil Water Centrifuge uses discs in the bowl to magnify the effective g-force, making them highly efficient at separating small traces of water and sludge from oil or the other way around. These centrifuges are also known as Disc Stack Separators.

Read our 101 Frequently Asked Questions about Disc Stack Centrifuges!

An oil centrifuge is a standard industrial separation device that finds various uses in various industries, from food and beverage to waste processing to chemical and crude oil production.

With its flow-through design, this centrifuge can continuously separate liquid from liquid and liquids from solids and other liquids.

Working Principle

An oil centrifuge works on the principle of differential settling using a high centrifugal force to separate oil from solid and liquid contaminants. The centrifuge exerts up to 10,000 Gs of force to separate particles as small as 1 micron from the oil. It also separates any immiscible liquid contaminants from the oil.

Benefits (Advantages)

An oil centrifuge offers several advantages over conventional filters and settling methods of separation. The following is a list of the essential advantages of these centrifugal separators.

- High Separation Efficiency: With a centrifugal force above 7,000 Gs, the oil centrifuge can separate small particles (0.5 microns) and all free water in a single pass.

- Separation of Water and Solids: Oil centrifuges are three-phase separators that separate water and sediment simultaneously.

- Compact Size: Oil centrifuges are relatively small for the capacity of oil they can process.

- Low Operating Cost: Unlike filters, centrifuges do not need filter media and the related labor and material cost, resulting in considerable savings.

- Emulsion Separation: An oil centrifuge can break simple oil in water or water in oil emulsions. However, chemically bonded emulsions need demulsifying chemicals for effective separation.

- Consistent Processing Capacity: Unlike filters whose flow capacity diminishes as the pores get blocked, a centrifuge capacity is consistent due to its mechanical separation.

Drawbacks (Disadvantages)

Like all industrial equipment, centrifuges also have certain disadvantages, which are listed below.

- Capital Expense: Compared to filters, centrifuges have a higher initial cost that pays off quickly due to lower operating costs.

- Maintenance: Centrifuges are mechanical machines that consist of moving parts and are subject to wear and tear. Routine maintenance is a part of centrifuge ownership.

- Noise and Vibration: Though oil centrifuges are relatively quiet during operation, they still generate noise and vibrations due to the rotation of the bowl. Filters, on the other hand, do not create noise or vibrate.

- Skilled Operator: Centrifuges need a trained operator to operate and service them. Filtration systems are less reliant on operators as compared to centrifuges.

- Auxiliary Systems: Oil centrifuges with self-cleaning mechanisms require additional auxiliary equipment, such as water harnesses, to operate the sludge discharge mechanism.

- Utilities: Oil Centrifuges need power and other utilities to operate. Filters are static separators that do not require utilities.

Size

Oil centrifuges are available in different sizes from Alfa Laval and other centrifuge manufacturers. The size typically ranges from 1 GPM to over 300 GPM. The physical size is proportional to the processing capacity of the centrifuge.

Capacity

The following table lists the capacities of different Alfa Laval oil centrifuges widely used for typical industrial and marine applications.

| Oil Centrifuge Model | Processing Capacity | ||

| Alfa Laval MAB-103 | Diesel: 3 GPM | ISO 32 Lube: 2 GPM | ISO 320 Lube: 1 GPM |

| Alfa Laval MAB-206 | Diesel: 25 GPM | ISO 32 Lube: 15 GPM | ISO 320 Lube: 8 GPM |

| Alfa Laval MOPX-205 | Diesel: 10 GPM | ISO 32 Lube: 6 GPM | ISO 320 Lube: 3 GPM |

| Alfa Laval WHPX-410 | Diesel: 40 GPM | ISO 32 Lube: 22 GPM | ISO 320 Lube: 10 GPM |

Dimensions & Weights

The following table lists the weights and dimensions of standard oil centrifuges.

| Oil Centrifuge Model | Dimensions | Weight |

| Alfa Laval MAB-103 | 2’ x 2’ x 2’ (H) Bare; 3’ x 4’ x 3’ (H) Skid | 250 Lbs; 600 Lbs (Skid) |

| Alfa Laval MAB-206 | 3’ x 4’ x 4’ (H) Bare; 4’ x 4’ x 5’ (H) Skid | 800 Lbs; 1800 Lbs (Skid) |

| Alfa Laval MOPX-205 | 3’ x 4’ x 4’ (H) Bare; 4’ x 4’ x 6’ (H) Skid | 600 Lbs; 1500 Lbs (Skid) |

| Alfa Laval WHPX-410 | 4’ x 5’ x 6’ (H) Bare; 5’ x 6’ x 7’ (H) Skid | 2500 Lbs; 3500 Lbs (Skid) |

Specifications

The following table lists the general specifications of the oil centrifuges commonly used and listed above for capacity and weights.

| Oil Centrifuge Model | Bowl RPM | Sludge Space | Motor HP | Startup Amps |

| Alfa Laval MAB-103 | 8,600 | 0.15 Gal | 1 HP | 2.4 A |

| Alfa Laval MAB-206 | 8,400 | 0.85 Gal | 2 HP | 3.6 A |

| Alfa Laval MOPX-205 | 7,600 | 0.38 Gal | 4 HP | 6.5 A |

| Alfa Laval WHPX-410 | 5,180 | 1.55 Gal | 10 HP | 22 A |

Material of Construction

The main components of an oil centrifuge typically have the following construction material. Depending on the application, some specially built centrifuges may have all stainless steel bowls.

Bowl

Bowl Body, Bowl Hood, Disc Stack – 316L Stainless Steel

Distributor, Top Disc, Cone, Level Ring – Marine Grade Bronze

Frame

Sludge Chute, Bottom Frame – Nodular Cast Iron

Covers – Silumin (Aluminum Alloy)

Types

Alfa Laval oil centrifuges are available in different types that are suitable for specific applications. The standard, most commonly used centrifuges are listed below.

Manual Clean

Manual clean oil centrifuges incorporate a design where the liquid phases continuously discharge from the centrifuge. After stopping the centrifuge, the centrifuge retains the separated solids in the bowl for manual extraction.

Automatic Self Clean

An oil centrifuge with an automatic self-clean feature does not require manual extraction of the separated sludge. The centrifuge bowl design allows the centrifuge to eject the separated sludge while still rotating automatically.

The separated oil and water exit the centrifuge continuously while the separated solids intermittently self-eject.

If you have simple, routine questions: We have condensed our 40+ years of disc-stack centrifuge experience into 101 Frequently Asked Questions about Disc Stack Centrifuges!

Examples of Applications

The following are examples of real-world oil centrifuge applications.

Lube Oil

All types of lube oil, from steam turbine oil to engine lubricating oil, need purification from fine metal contaminants and occasionally moisture. An oil centrifuge is ideal for processing large volumes of lube oil to a high purity level without filters. Simultaneous removal of water is an added advantage.

Diesel Fuel

Diesel fuel stored in tanks has rust, sediment, and other contaminants along with water from condensation. An oil centrifuge installed in a kidney loop on the storage tank keeps the fuel’s solids and liquid contaminants clean.

Fuel Oil

Fuel oil is a common energy source for most power plants, and large marine engines need to be maintained free of contaminants. A fuel oil centrifuge is a reliable separating machine that removes all sludge and water from fuel oil to keep it usable.

Cutting Oil

A wide variety of industries use cutting oil for various metal-forming applications. This oil picks up solid metal particles during processing. It is essential to remove these particles from the oil for its reuse.

An oil centrifuge can separate 0.5-micron metal particles from the oil, thus making the oil reusable and reducing replacement costs.

Costs

We have broken down the cost of oil centrifuges into the following categories.

Equipment Cost

A small ‘manual clean’ oil centrifuge with a processing capacity of 3 GPM is around $15K for the bare centrifuge, and a high capacity (100 GPM) costs over $120K. Remanufactured centrifuges typically cost around 60% of new centrifuges.

Optional accessories add to the system cost and can be more than the bare centrifuge cost, depending on the options chosen.

Operating Cost

The only operating cost of an oil centrifuge is the cost of electricity to drive the motor. Since the centrifuge is a mechanical separator, it does not use any media or replaceable elements that add to operating costs.

Therefore, the typical operating cost per gallon of an oil centrifuge is a fraction of a cent!

Maintenance Cost

Like most mechanical equipment, oil centrifuges require routine maintenance. The maintenance costs associated with an oil separator are for the spare parts. The frequency of maintenance depends on the application and type of centrifuge.

Detailed cost estimates of maintenance costs related to Alfa Laval oil centrifuges are listed here.

Plant Layout Configuration

Typical configurations of an Industrial Oil Cleaning Centrifuge include:

- Waste Oil Centrifuges for Oil Recycling, Industries, Refineries, etc.

- WVO Centrifuges for Used Vegetable Oil, Yellow Grease, UCO, Used Engine Oil or Motor Oils, etc.

- Diesel Centrifuges for Used/Contaminated Diesel from diesel cleaning operations.

- Centrifugal Oil Water Separators for wash water contaminated with an oil slick.

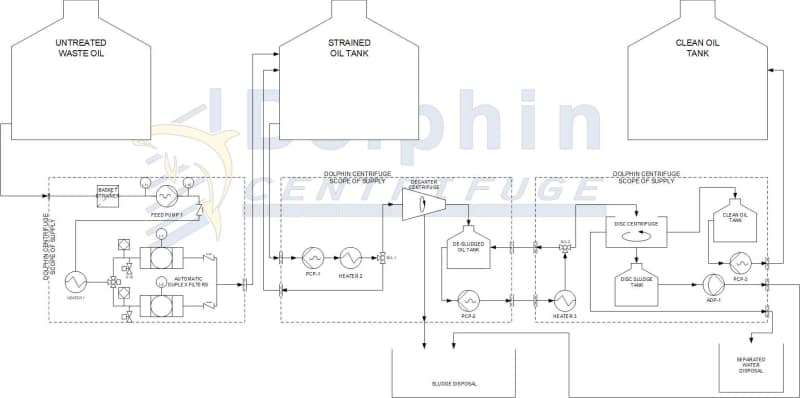

For example, a typical layout of an industrial centrifuge setup for waste oil is shown below.

The system consists of 3 steps needed for oil, water, and sludge processing at high capacity.

- Pre-Straining Module – separates debris (i.e., rocks, debris, bolts, etc.) from the untreated waste oil.

- Decanter Centrifuge Module – to de-sludge the pre-strained oil to separate the bulk of the sludge.

- Vertical Disc Centrifuge Module – for oil-water separation and to remove small particles down to 1-micron level.