Considering purchasing an industrial centrifuge but unsure where to begin? Even after thorough research, it’s common to have lingering doubts and questions. Industrial centrifuges are significant capital investments that require meticulous consideration. With our 40 years of expertise in the industrial centrifuge sector, we guide prospective buyers toward making informed decisions. We’ve distilled the centrifuge… Continue reading 9 Steps to Picking The Right Industrial Centrifuge

Tag: disc stack centrifuge

Alfa Laval Diesel Centrifuge: Large Scale Application Case Study

Alfa Laval Diesel Centrifuge: Large Scale Application Case Study This case study is related to applying an Alfa Laval diesel centrifuge for the large-scale recovery used diesel fuel that is used for washing crude oil railcars. The Source of Contaminated Diesel Railcars transporting crude oil need periodic cleaning. This is to remove accumulated sludge, waxes,… Continue reading Alfa Laval Diesel Centrifuge: Large Scale Application Case Study

Waste Oil Emulsion Breaking with an Industrial Centrifuge

Synopsis Disc-stack type industrial centrifuges exert a very high centrifugal force on emulsified oils. This force can break waste oil emulsions by mechanical separation. Thus, industrial centrifuges recover clean oil from waste oil emulsion on a large scale. What is an emulsion? When two immiscible liquids mix to form one liquid phase – that combined… Continue reading Waste Oil Emulsion Breaking with an Industrial Centrifuge

Difference Between Decanter and Disc Centrifuge | Technical Comparison

30-Second Take-Away The main differences between a decanter and disc-stack centrifuge are: This article compares the different technical aspects of decanter centrifuges and disc centrifuges. We will compare all the factors important to the end-user. These will include physical, operational, performance, and maintenance factors between these centrifuge types. Overview of Decanter and Disc Centrifuge Operation… Continue reading Difference Between Decanter and Disc Centrifuge | Technical Comparison

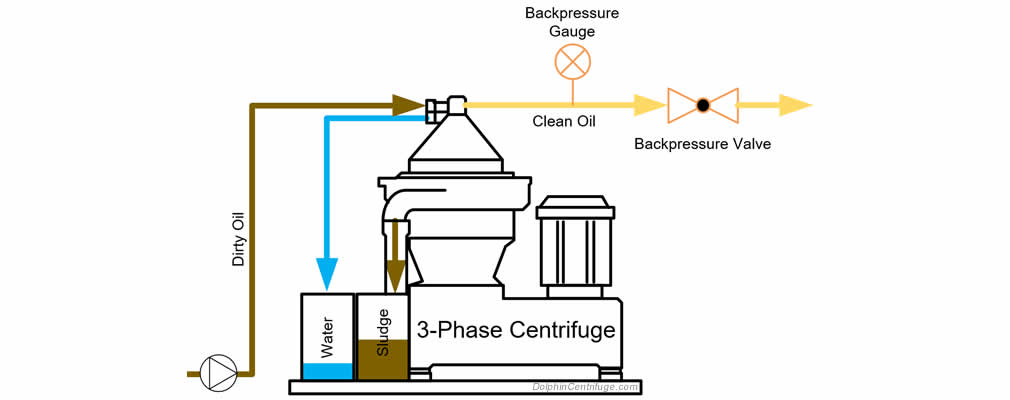

Tramp Oil Removal Using an Alfa Laval 3-Phase Disc-Stack Centrifuge

Tramp Oil Tramp oil is an undesirable phase of hydrocarbon oil contaminant found in machining coolants and washer fluids. This floating oil is a by-product of industrial machining operations contaminating the water-based coolant. Tramp oil removal from machining coolants is critical to the maintenance of coolants. Where does tramp oil originate? The various components of… Continue reading Tramp Oil Removal Using an Alfa Laval 3-Phase Disc-Stack Centrifuge

Disc Stack Centrifuge Performance – 8 External Factors

Disc stack centrifuge performance depends on several factors that are internal and external. Internal factors are those which are related to the centrifuge and the process fluid. We will discuss the external factors here. You can also read our blog about internal factors that affect centrifuge efficiency. Read our 101 Frequently Asked Questions about Disc… Continue reading Disc Stack Centrifuge Performance – 8 External Factors

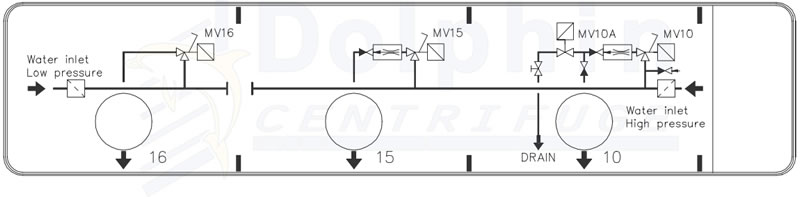

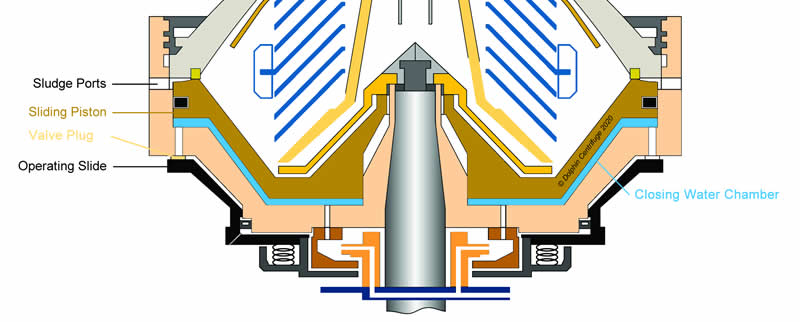

7 Key Things to Know About Disc Stack Centrifuge Operating Water

What is Disc Stack Centrifuge Operating Water? All self-cleaning disc-stack centrifuges have a hydraulic mechanism that operates the sludge ejection system. The centrifuge uses water as the medium of operation of this system, known as centrifuge operating water. How Does the Centrifuge Use Operating Water? The operating water serves two primary functions in the sludge… Continue reading 7 Key Things to Know About Disc Stack Centrifuge Operating Water

Disc Stack Centrifuge | Sludge Ejection Cycle Time Calculation

One of the essential features of a self-cleaning disc centrifuge is to eject the separated solids while operating. The frequency of this ejection process is crucial to the process efficiency and centrifuge wellbeing. This article discusses the various aspects of the sludge ejection cycle time, from calculating the cycle time to the results of incorrect… Continue reading Disc Stack Centrifuge | Sludge Ejection Cycle Time Calculation

Pyrolysis Oil Centrifuge Application: Large Scale Production from Tires

In this real-world case study, we will discuss the applicability of a pyrolysis oil centrifuge and its application for the large-scale production of bio-oil from used tires. Pyrolysis Process – Brief Description Solid organic material (mostly petroleum-based), such as plastics, tires, etc., disintegrates into solid and liquid phases at elevated temperatures. This reaction occurs without… Continue reading Pyrolysis Oil Centrifuge Application: Large Scale Production from Tires

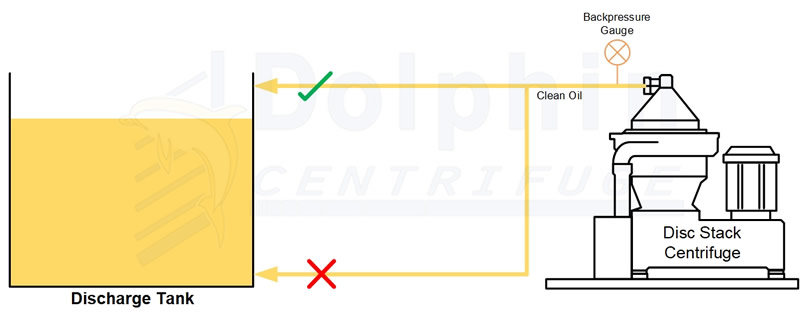

Disc Centrifuge Backpressure | A Comprehensive Guide

What is Backpressure in Disc Centrifuges? A paring disc pump within the disc centrifuge bowl converts the rotational momentum of the fluid into pressure. This pressure causes the liquid to discharge out of the bowl. Any restriction in the discharge passage of the liquids exerts pressure on the bowl. This externally created pressure is known… Continue reading Disc Centrifuge Backpressure | A Comprehensive Guide