Table of Contents

Synopsys

The food processing industry generates millions of gallons of contaminated Waste Vegetable Oil (WVO) annually. This used edible oil has commercial value, and an industrial WVO centrifuge is the most efficient way to separate the oil from water and solid impurities.

Compared to commercial (open bowl) centrifuges, a disc-stack type industrial centrifuge generates a very high centrifugal force and has an effective settling area, which is thousands of times larger.

For large-scale processing of WVO, an industrial centrifuge is a robust and durable solution for used cooking oil recovery.

Waste Vegetable Oil (WVO), Used Cooking Oil (UCO)

The terms mentioned above describe edible oil used in food processing and is no longer useful for cooking purposes due to degradation and contamination from cooking byproducts.

What is WVO?

WVO is an abbreviation for Waste Vegetable Oil. Waste vegetable oil is a general term for all kinds of used edible oils. Used Cooking Oil (UCO) and Yellow Grease are other terms for waste vegetable oil.

Sources and Composition

Cooking oil, fryer oil, grease trap waste, yellow grease, etc., comprise UCO. Also, used edible oil, such as palm oil, canola oil, and peanut oil, is a primary WVO source. Other fats, such as chicken fat, beef lard, fish oil, etc., are also present in waste vegetable oil.

Typical Contaminants

Water is the primary contaminant of WVO. It can come from the water in the fried food to wash water from food prep. Soapy wash water from cleaning activities also adds to the water content of used cooking oil.

In the presence of soap (detergent), water and oil combine to form an emulsified phase. This emulsion is also known as the ‘rag layer.’ We discuss this emulsion processing in detail further down in this article.

Solids or sludge is the other contaminant in WVO. Flour, crumbs, organic particles, bone fragments, sand, etc., turn into sludge.

Uses of purified WVO

Feedstock for biodiesel production is the primary use of purified WVO. Biodiesel processing requires clean WVO without any water or sludge.

Biodiesel procedures prefer the least FFA (Free Fatty Acids) in their feedstock. Neutralizing FFA in the WVO is essential before making biodiesel.

Diesel engines use clean WVO as fuel. Lubricant or feedstock for lubricant manufacturing is another use. Residential and commercial heating uses low-quality (not purified) WVO fuel.

Other uses of WVO include manufacturing soap, cosmetics, clothing, elastomers, etc.

The sludge separated during WVO purification has nutritional value. It retains fat and other nutrients from processed foods. WVO sludge is a good animal feed additive.

WVO Centrifuge

A WVO Centrifuge is an industrial centrifuge designed to remove water and solid impurities (sludge) from Waste Vegetable Oil (WVO). It is a three-phase, industrial, disc-stack centrifuge that continuously separates the used edible oil from free water and fine sediment down to a 1-micron level.

Operation

A WVO centrifuge exerts a high centrifugal force (up to 8,000 Gs) on the used oil. This force causes the sludge and water to separate from the WVO, and the separated water and clean oil exit the centrifuge through separate passages. The self-cleaning process of the centrifuge periodically discharges the separated sludge.

Waste Vegetable Oil Centrifuge Specifications

| Centrifuge Model | DMPX-014 | DMPX-042 |

| Type | Self-Cleaning Disc Stack | Self-Cleaning Disc Stack |

| Efficiency | Solids > 1 µ; Water > 2 µ | Solids > 1 µ; Water > 2 µ |

| Rated Capacity | 23 GPM | 69 GPM |

| WVO Capacity @ 180F | 15 GPM | 45 GPM |

| Bowl Speed | 8,500 RPM | 5,180 RPM |

| Sludge Space | 0.36 Gal | 1.55 Gal |

| Motor Power | 5 HP | 15 HP |

| Dimensions | 4′ x 5′ x 6′ (H) | 5′ x 6′ x 7′ (H) |

| Weight | 1,500 Lbs | 3,500 Lbs |

| Power | 460V AC; 3-Phase | 460 V AC; 3-Phase |

Emulsified WVO Separation

Emulsified oil is also broken down into oil and water by the centrifuge. The percentage of emulsion separated depends on the presence of soaps. Acid or other demulsifying chemicals help emulsion separation.

Emulsion breaking releases more oil for the producer. Read about waste oil emulsion breaking with an industrial centrifuge here.

How well does an industrial centrifuge purify the WVO?

A disc-stack type industrial centrifuge can produce 99% or better clean oil from WVO. Processing temperature and centrifuge tuning are critical to high separation efficiency.

The separated water phase contains trace amounts of oil. Further tuning of the centrifuge can reduce this oil in water to a minimum level for water disposal.

WVO solids separated by an industrial centrifuge come out as thick sludge. It is pumpable sludge but not runny. Oil content in this sludge varies from 10% to 50%, depending on the centrifuge settings and processing temperature.

Benefits of Disc Centrifuge versus Open Bowl (Disc-Less) Centrifuge and Filters

| Disc Centrifuge | Open Bowl Centrifuge | Filtration | |

| Centrifugal Force (Gs) | 8,000 ~ 10,000 | 500 ~ 1,500 | N/A |

| Construction | Industrial Grade | Commercial Grade | Industrial Grade |

| Bowl Material | 316L Stainless Steel | Aluminum or Carbon Steel | All Material (Housings) |

| Capacity (Gallon/Minute) | 3 ~ 100+ | 0.1 ~ 7 | 1 ~ 500+ |

| Separation Efficiency | 0.5 Micron | 100 Micron | 0.1 Microns |

| Water Separation | Continuous (Any Proportion) | Not Capable | Not Capable |

| Sludge Removal | Automatic During Operation | Manual (Stop Centrifuge) | Manual |

| Operating Mode | Continuous | Batch | Batch |

| Equipment Cost | High | Low | Cheap |

| Labor Cost | None | Medium | Very High |

| Media Cost | None | Noce | Very High |

Installation

The following image shows the installation of a WVO centrifuge package designed and manufactured by Dolphin Centrifuge. This installation is currently operational in the NE and has processed over 10 million gallons of WVO!

The ancillary equipment for maximum throughput from a WVO centrifuge are:

- Operating Water Supply: Filtered, potable, soft water is essential for the trouble-free operation of the self-cleaning mechanism of the disc stack centrifuge. The supply pipe should provide a minimum flow rate and should be made of a non-corrosive material such as copper, PVC, or stainless steel.

- Hot Water Boiler: For optimum separation, operating water should be at a temperature close to that of the process fluid i.e., hot. A water heater is a good investment to ensure high separation efficiency.

- Local Clean Oil Receptacle: A local receptacle (tank) to collect the separated clean WVO prevents back pressure from being exerted on the centrifuge outlet from a long, elevated discharge pipe. Disc stack centrifuges work best with consistent back pressure.

- Elevated Platform with Service Deck: An elevated platform with an operator service deck has two functions. First, it allows for placing a sludge tank below the centrifuge to collect the separated sludge. Second, the deck allows easy and safe access for the operator for service and operational adjustments.

WVO Centrifuge Plant Setup

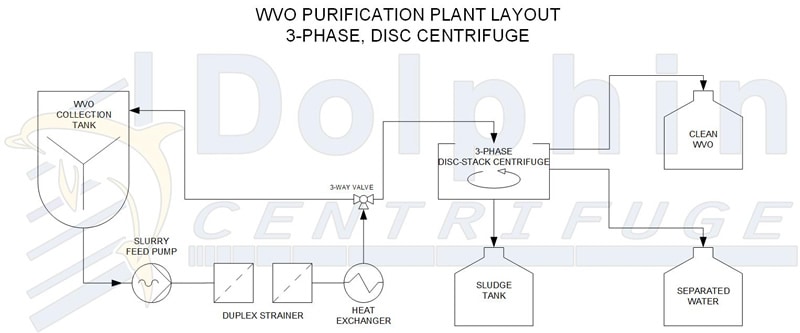

The diagram below shows a typical centrifuge-based WVO/UCO/Brown-Grease recovery plant layout. A description of each step of the process follows the schematic.

Would you please read our article about using our disc-stack centrifuge for yellow grease purification?

WVO Collection Tank (Agitated)

The incoming collected WVO is dumped into the collection tank, as shown. This tank is typically agitated to keep the sludge from settling. It is advisable to keep this tank heated to reduce the thermal load on the system heater. Special consideration is given to the tank design to alleviate sludge-blocking issues.

Slurry Feed Pump

The feed pump is a positive displacement pump with a high sludge handling capacity. It functions to transfer the raw WVO to the centrifuge or back to the tank in bypass mode.

In this bypass mode, the pump also acts as an agitator to keep the tank from settling. We must protect the pump from WVO-specific issues, which we design into our system.

Duplex Strainer

The duplex strainers protect the downstream centrifuge from damage from large solid contaminants such as rocks, debris, twigs, rags, bones, etc. We recommend specially designed strainers for quick change and long-term durability of the equipment.

Decanter Centrifuge

A decanter centrifuge is a continuous (flow-through) centrifuge that can de-sludge Grease Trap Waste (GTW) with up to 50% solids, and down to 1% solids. This centrifuge is ideal for large-scale processing of WVO and can process 25 GPM of GTW at around 150 F.

Heat Exchanger

For maximum centrifuge separation efficiency, the WVO needs to be hot! The ideal processing temperature is around 180 F. An inline heater (or heat exchanger) is perfect because it only heats the oil in the process instead of heating the entire tank of 1000 gallons.

We have specially designed heaters, which are gentle heating to avoid overheating and burning of the UCO.

3-Way Valve

This 3-way valve works as a diverter valve to recirculate the oil when the centrifuge is not ready for processing or cleaning mode. Our PLC automatically operates it with many process parameters influencing this valve’s operation and position.

Alfa Laval 3-Phase Disc Centrifuge

The centrifuge is the heart of the system where the separation takes place. A previous section describes the purpose of this device and its operation.

Sludge Tank

The ‘self-cleaning’ WVO centrifuge ejects the sludge through the bottom of the centrifuge frame. Therefore, a sludge receptacle is placed under the centrifuge to collect the separated sludge.

Our system integrates this sludge tank into the centrifuge base skid as an option. This design feature allows the centrifuge package to be mobile and is not fixed to a location.

Clean Oil Tank

Most self-cleaning Alfa Laval centrifuges discharge the clean oil under pressure. Therefore there is adequate pressure to transfer the pure oil to a local clean oil tank. We also offer an optional upgrade to our WVO centrifuge system wherein this clean oil tank is integrated into the skid.

Separated Water Tank

The water separated by the centrifuge is also discharged under pressure by most disc centrifuges. Depending on the WVO’s anticipated water contamination, the centrifuge may need to be modified to ensure maximum throughput efficiency.

Discharging the separated water into the local drain is often possible, but we recommend storing the separated water before discharge to verify oil levels.

Also, read our Alfa Laval Centrifuge Selection Guide.

Auxiliary and Recommended Accessories

Our WVO centrifuge packages typically include sample ports, sight glasses, flow meters, flow sensors, temperature monitors, and other process-enhancing features.

However, we recommend customers procure some additional accessories to understand and draw the maximum benefits from the centrifuge skid. A detailed description and source of each of these accessories are available to our customers.

WVO Centrifuge Packaged Systems

Shown at the bottom are WVO / UCO centrifuge packages of different capacities featuring Alfa Laval centrifuges.

Alfa Laval Self-Cleaning WVO Centrifuge

Capacity: 10 GPM on Used Cooking Oil

Motor: 7.5 HP

Voltage: 230V/ 460V

Skid Dims: 5′ x 5′ x 6′ (H)

Alfa Laval WHPX 510 WVO Centrifuge

Capacity: 25 GPM on Used Cooking Oil

Motor: 15 HP

Voltage: 230V/ 460V

Skid Dims: 5′ x 6′ x 8′ (H)

Summary

Various ways and equipment are available to clean WVO to recover clean, sale oil. If it is a small-scale operation (<100 Gallons/Day), a simple heat, settle, and filter process will work.

However, serious consideration must be given to our robust, durable, high-speed, high-G centrifuge for larger volumes. These centrifuges produce clean WVO continuously and separate the water at high throughput capacities.